Technical Drawing Symbols

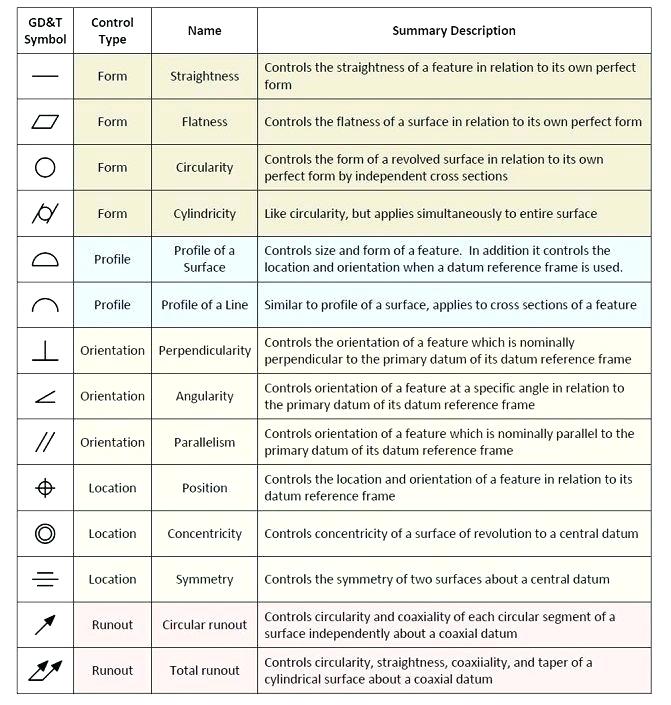

Technical Drawing Symbols - Web engineering drawing abbreviations are a set of standardized symbols and abbreviations used on engineering drawings to represent common terms and phrases. Toleranced characteristics and symbols — examples of indication and interpretation Terms relating to technical drawings: Web tolerances are specified, and each symbol has a clearly defined meaning. This list includes abbreviations common to the vocabulary of people who work with engineering drawings in the manufacture and inspection of parts and assemblies. These symbols usually represent measurements, dimensions, angles, and other specifications related to the object being drawn. Here are more commonly used engineering drawing symbols and design elements as below. Symbols take less time to apply on a drawing than would be required to state the same requirements with words. The following tables show how to construct the symbols. The symbols also require considerably less space. Working drawings are the set of technical drawings used during the manufacturing phase of a product. Edges of undefined shape ? In addition, knowledge of the software used to create the drawings is required. The characteristics are grouped into four types of tolerance: The symbols and abbreviations represent various components, processes, and measurements used in engineering design. Radius can be for the inside and outside curved surface on the part. You can also check out the gd&t symbols and terms on our site. Web engineering drawing abbreviations are a set of standardized symbols and abbreviations used on engineering drawings to represent common terms and phrases. Web the included collection of predesigned mechanical drafting symbols, machining drawing symbols,. Web this page explains the 16 symbols used in gd&t, and the classification thereof. In order to communicate accurately in any written language, the writer and the reader must share the same understanding of the symbols and structure of that language. If you’re studying engineering and need a reference sheet for these drafting symbols, you’ve come to the right place.. Form, orientation, location, and runout. The symbols and abbreviations represent various components, processes, and measurements used in engineering design. Vocabulary and indications on drawings [12] In addition, knowledge of the software used to create the drawings is required. Here are more commonly used engineering drawing symbols and design elements as below. The characteristics are grouped into four types of tolerance: These symbols are placed in the first compartment of a feature control frame and define the geometry characteristic of the feature that is to be controlled. Radius can be for the inside and outside curved surface on the part. If you’re studying engineering and need a reference sheet for these drafting. Vocabulary and indications on drawings [12] You can also check out the gd&t symbols and terms on our site. The characteristics are grouped into four types of tolerance: Web geometric dimensioning and tolerancing symbols you can either create your own library of gd&t symbols, or use one of autocad’s gd&t fonts to insert the symbols as text. Web there are. Web this page explains the 16 symbols used in gd&t, and the classification thereof. General and types of drawings [11] iso 13715:2000, technical drawings ? Working drawings are the set of technical drawings used during the manufacturing phase of a product. Web tolerances are specified, and each symbol has a clearly defined meaning. Here are more commonly used engineering drawing. Edges of undefined shape ? Gd&t is such a standard for assembly design and production. Web basic types of symbols used in engineering drawings are countersink, counterbore, spotface, depth, radius, and diameter. Equivalent symbol and note 1.2 the symbols are presented in two groups for easier. This article provides an overview of technical drawings. The true position theory and the specification of tolerance zones are also explained. Web iso 6433:1981, technical drawings ? Web tolerances are specified, and each symbol has a clearly defined meaning. Any needed height h 2 h h 2 h 60° 2 h identification letter datum feature symbol datum target symbol target point and. Radius can be for the inside. In addition, knowledge of the software used to create the drawings is required. The true position theory and the specification of tolerance zones are also explained. Edges of undefined shape ? These symbols are placed in the first compartment of a feature control frame and define the geometry characteristic of the feature that is to be controlled. If you’re studying. The need for precise communication in the preparation of a functional document distinguishes technical drawing from. Equivalent symbol and note 1.2 the symbols are presented in two groups for easier. Web once you know what type of drawing you're looking at, take some time to familiarize yourself with the common symbols used in technical drawings. The characteristics are grouped into four types of tolerance: Web basic types of symbols used in engineering drawings are countersink, counterbore, spotface, depth, radius, and diameter. Gd&t is such a standard for assembly design and production. This article provides an overview of technical drawings. The symbols and abbreviations represent various components, processes, and measurements used in engineering design. Web tolerances are specified, and each symbol has a clearly defined meaning. Web geometric dimensioning and tolerancing, or gd&t for short, is a language of symbols used to communicate information on technical drawings. Toleranced characteristics and symbols — examples of indication and interpretation Web there are 12 geometric tolerancing characteristics with the corresponding symbols shown. In addition, knowledge of the software used to create the drawings is required. The symbols also require considerably less space. Symbols take less time to apply on a drawing than would be required to state the same requirements with words. In the last chapter ( design inputs & reviews ), we covered the three phases of product design which often result in the creation of detailed engineering drawings associated with your new product.

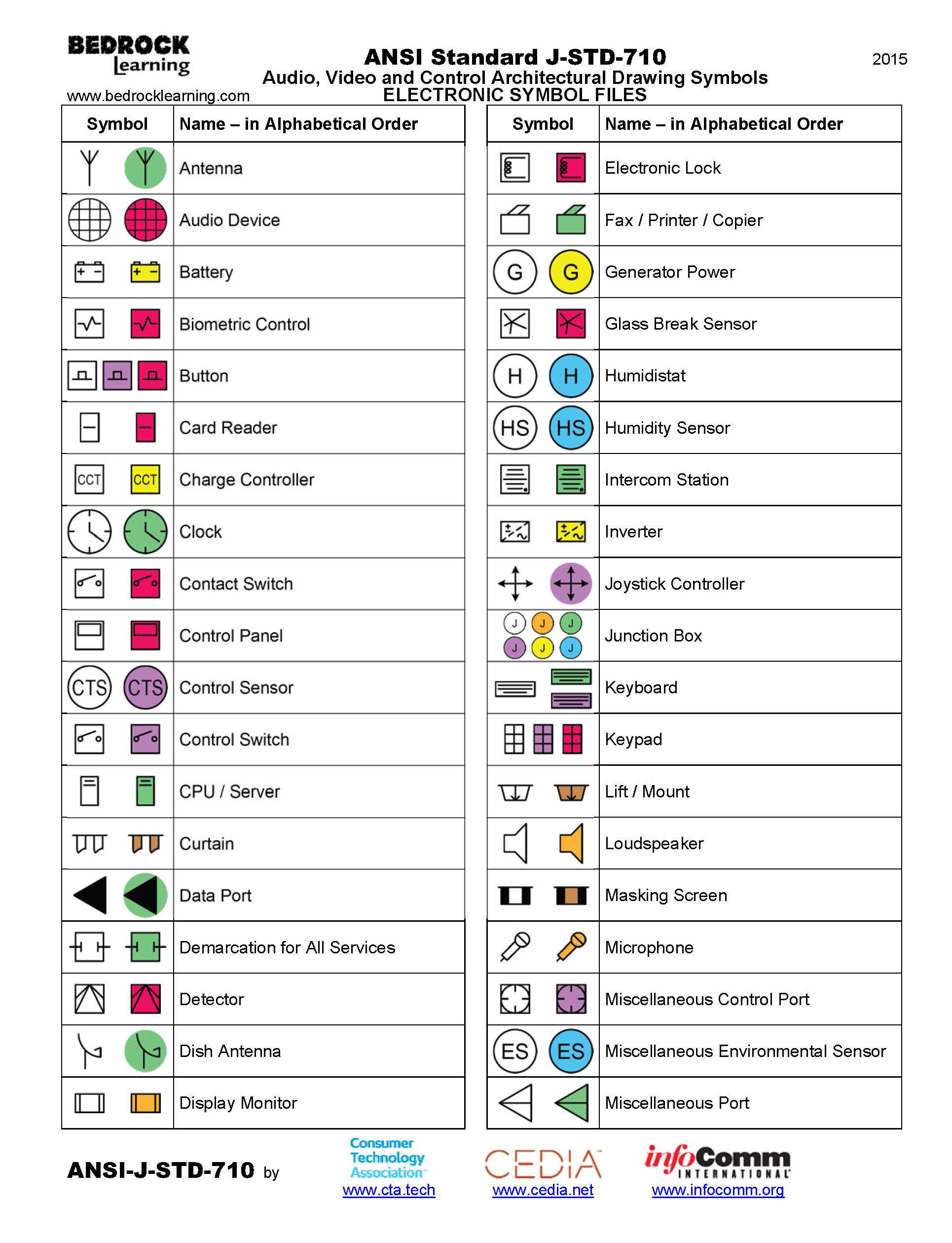

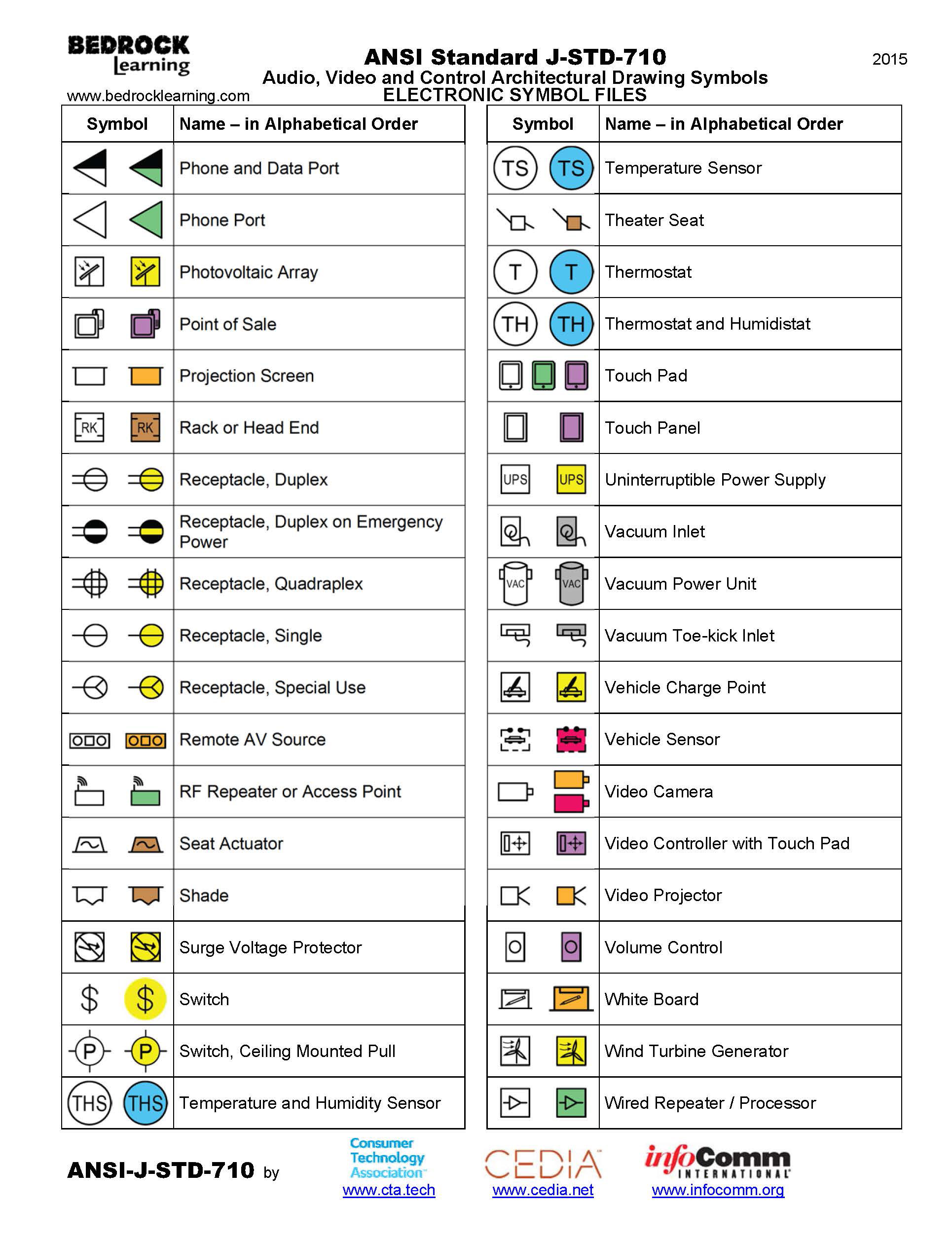

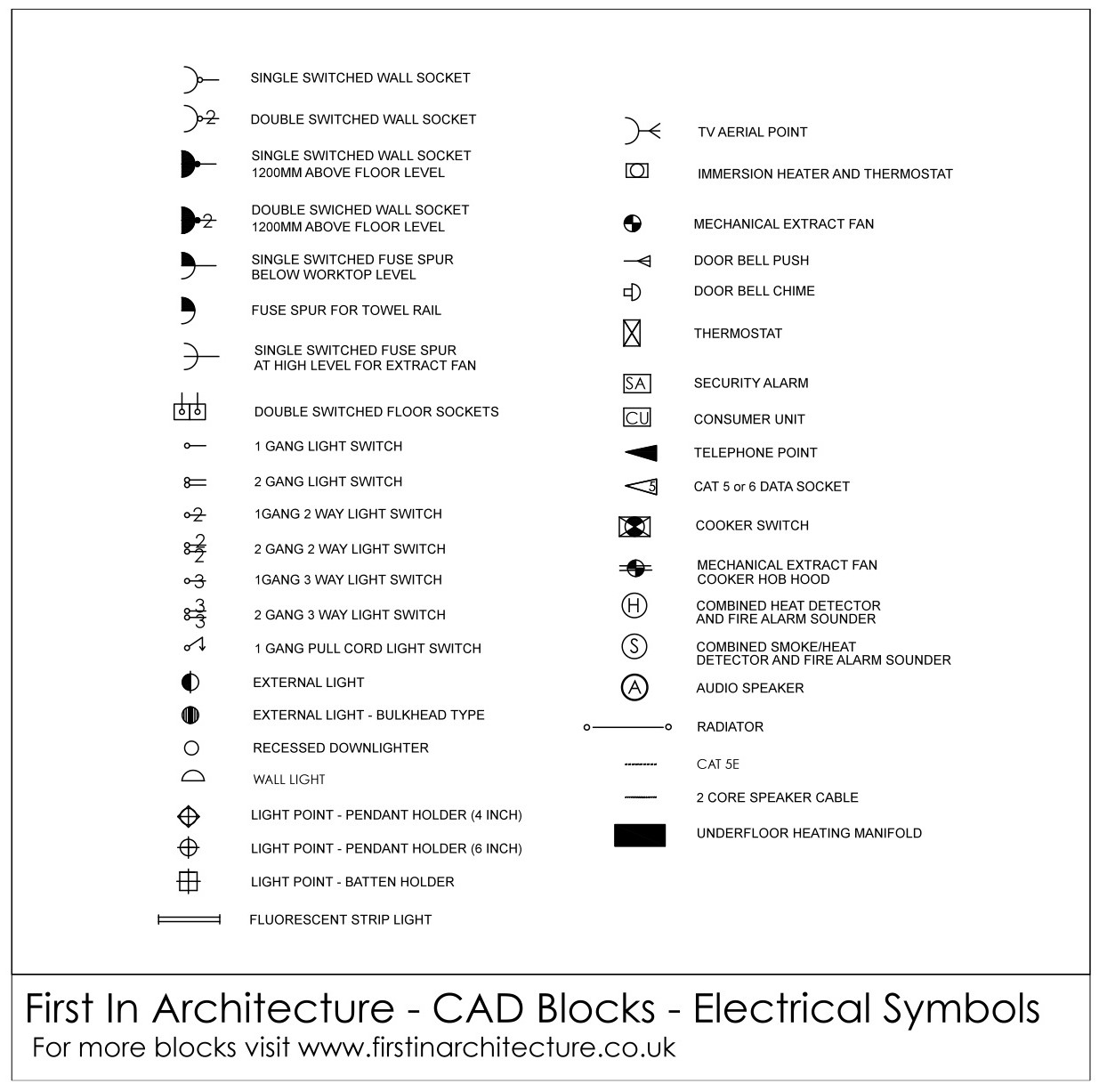

ANSI Standard JSTD710 Architectural Drawing Symbols Bedrock Learning

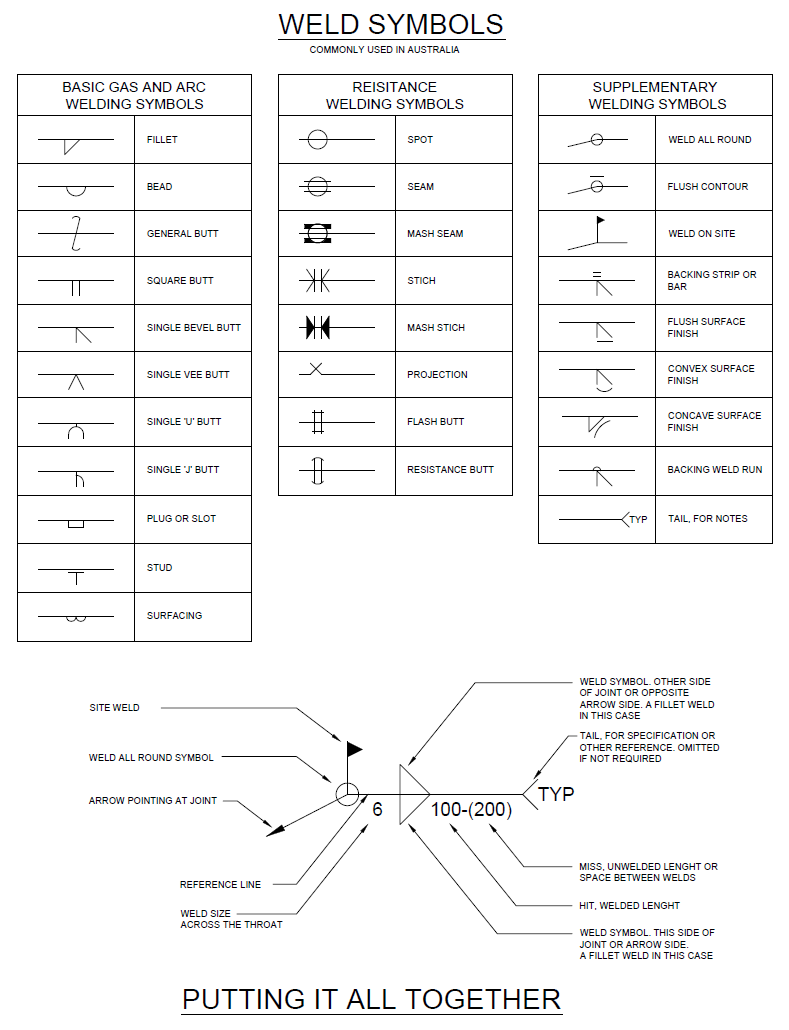

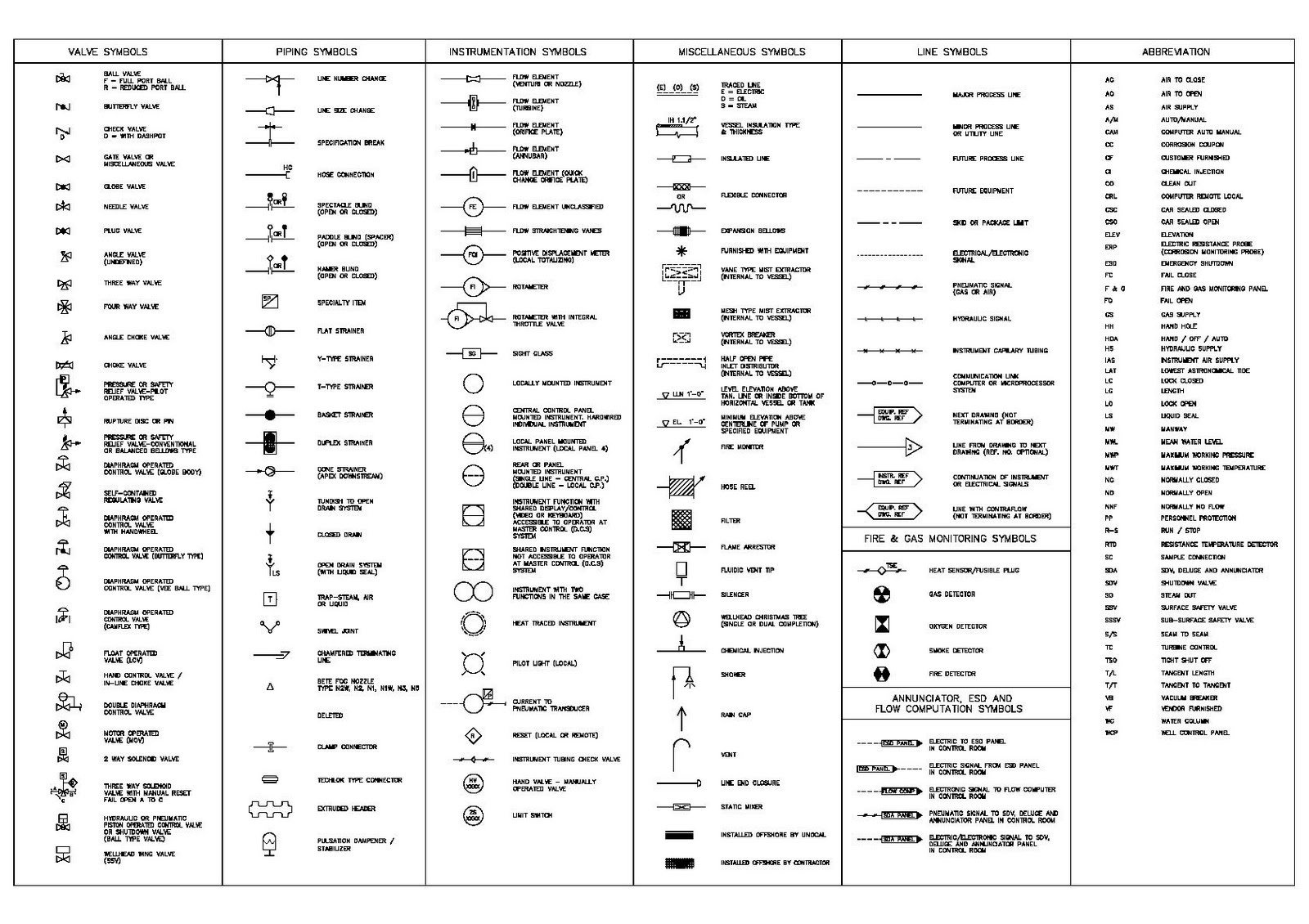

Civil Engineering Drawing Symbols And Their Meanings at PaintingValley

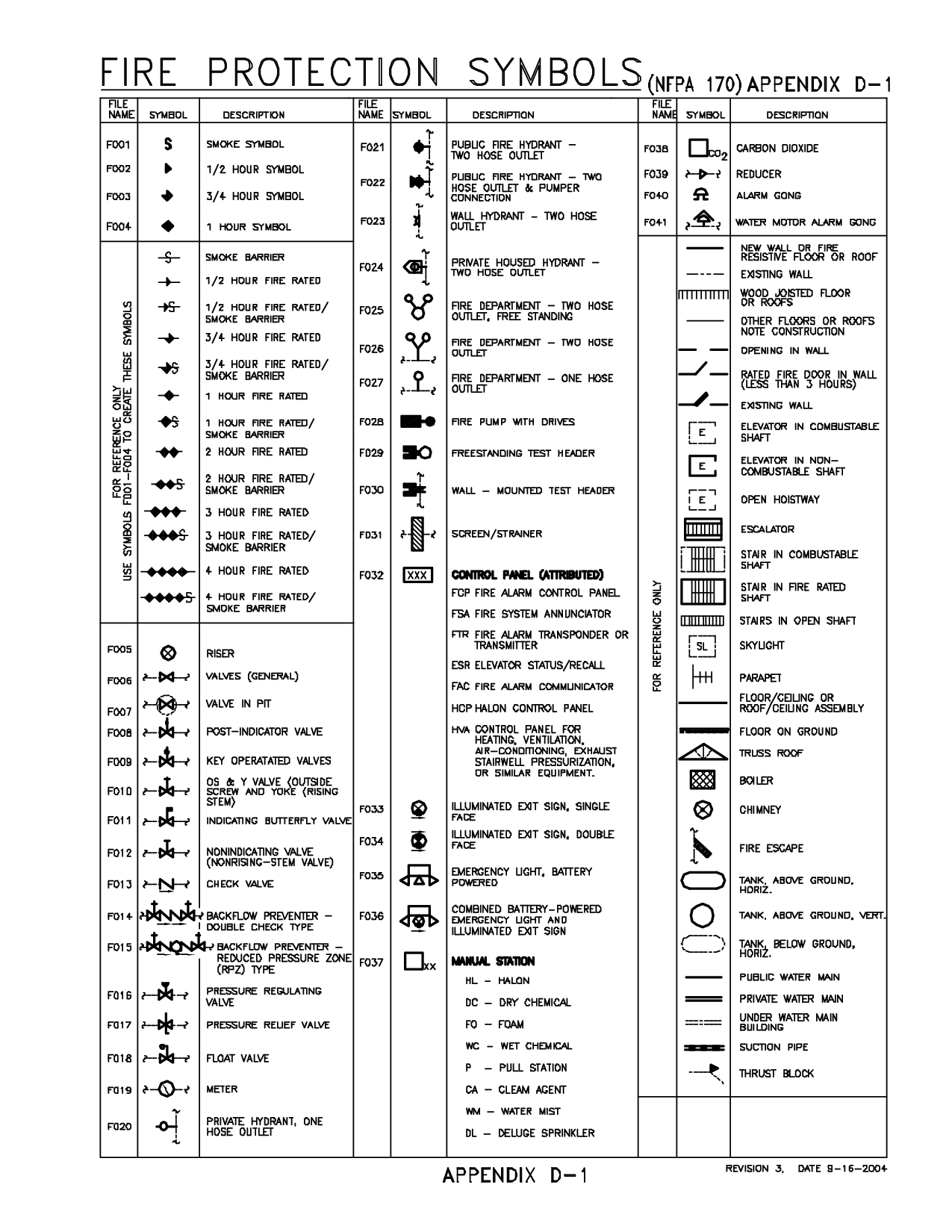

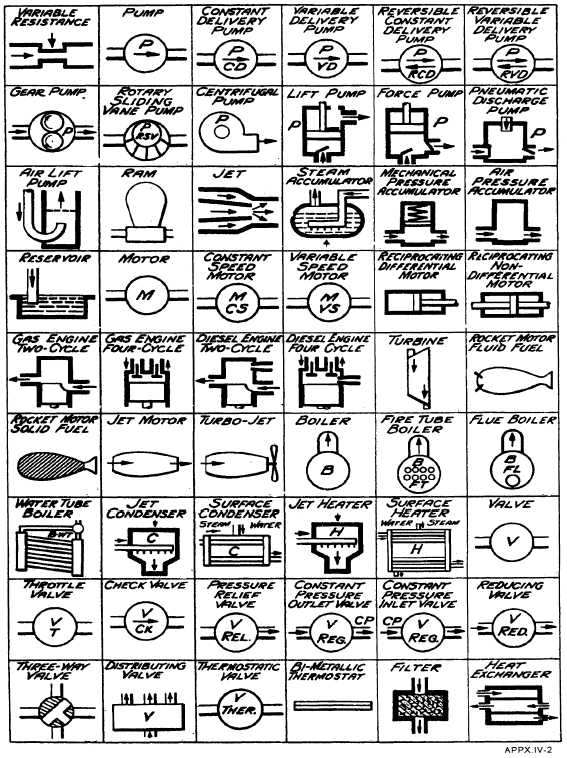

Engineering Drawing Symbols And Their Meanings Pdf at PaintingValley

Engineering Drawing Symbols And Their Meanings Pdf at PaintingValley

ANSI Standard JSTD710 Architectural Drawing Symbols Bedrock Learning

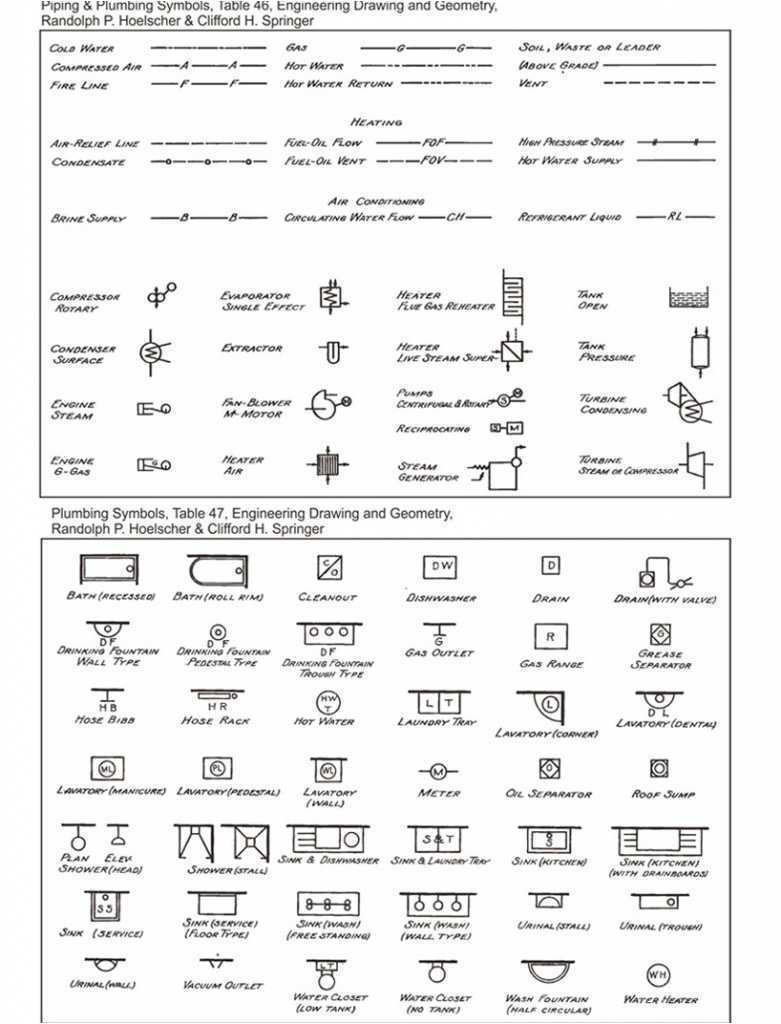

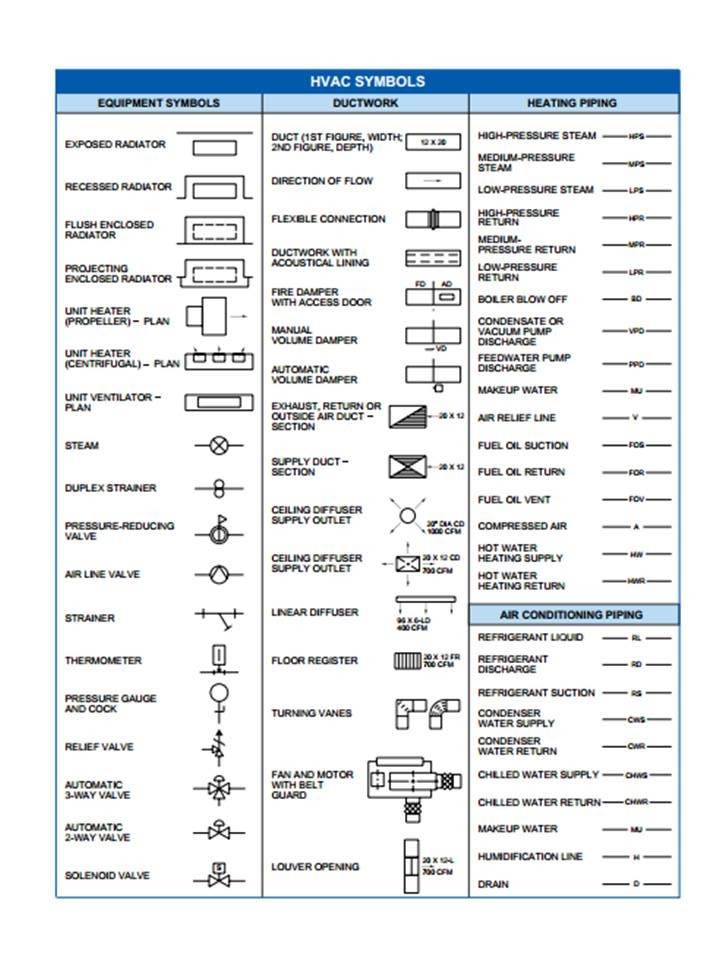

Mechanical Engineering Drawing Symbols Pdf Free Download at

Mechanical Engineering Drawing Symbols Pdf Free Download at

Civil Engineering Drawing Symbols And Their Meanings at PaintingValley

Engineering Drawing Symbols And Their Meanings Pdf at PaintingValley

Engineering Drawing Symbols And Their Meanings Pdf at PaintingValley

Any Needed Height H 2 H H 2 H 60° 2 H Identification Letter Datum Feature Symbol Datum Target Symbol Target Point And.

Web The Base Of Effective Rules Is The Common Standard.

These Symbols Are Placed In The First Compartment Of A Feature Control Frame And Define The Geometry Characteristic Of The Feature That Is To Be Controlled.

In Order To Communicate Accurately In Any Written Language, The Writer And The Reader Must Share The Same Understanding Of The Symbols And Structure Of That Language.

Related Post: