Engineering Drawing Dimensioning Rules

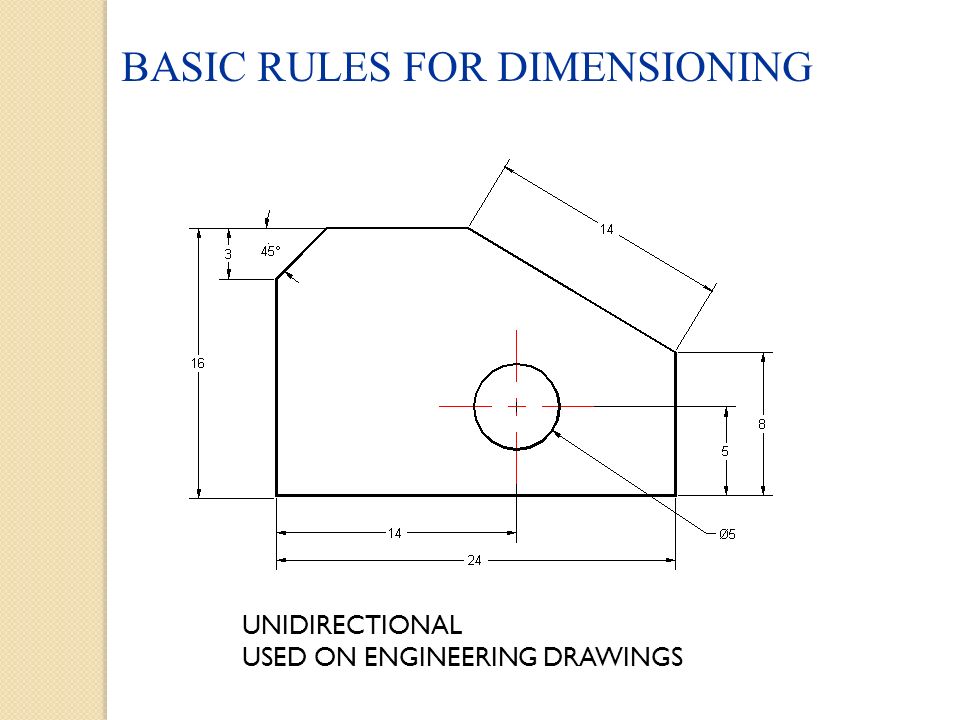

Engineering Drawing Dimensioning Rules - Correct values must be given. Web it establishes symbols, rules, definitions, requirements, defaults, and recommended practices for stating and interpreting gd&t and related requirements for use on engineering drawings, models defined in digital data files, and in related documents. Dimensions are expressed in specific units on the drawing with relevant information. How the geometric system works: Web three principles of dimensioning must be followed: Web every dimension must have an associated tolerance, and that tolerance must be clearly shown on the drawing. Web additional and more specific rules and details about the use of dimensioning for construction engineering are given in iso 6284. On a multiview drawing, dimensions should generally be placed between adjacent views. Complete engineering drawing exam preparation. Each dimension should be given clearly so it can be interpreted in only one way. Rule #1, size controls form. A complete set of dimensions will permit only one interpretation needed to construct the part. 23k views 3 years ago engineering drawing and it's basics. Dimensions should be placed in the view which most clearly describes the feature being dimensioned. Web dimensioning is the process of defining the size, form and location of geometric features. A complete set of dimensions will permit only one interpretation needed to construct the part. Web the dimensions in the part drawing shall be marked in accordance with the standard, complete, clear and reasonable. This youtube channel is dedicated to teaching people how to improve their technical drawing skills. Rule 1) dimensions should be arranged for maximum readability. Web it. Asme y14.37 2019 product definition for composite parts standard. Dimensions must be placed in appropriate positions. Web the gsfc engineering drawing standards manual is the official source for the requirements and interpretations to be used in the development and presentation of engineering drawings and related documentation for the gsfc. Web the dimensions in the part drawing shall be marked in. Rule #1, size controls form. 23k views 3 years ago engineering drawing and it's basics. Asme y14.37 2019 product definition for composite parts standard. This youtube channel is dedicated to teaching people how to improve their technical drawing skills. Web dimensioning practice once the shape of a part is defined with an orthographic drawing (i.e., in projections), the size information. Web the engineering drawing rules are defined and embodied in the publications of standards organizations (for example, iso and asme ). Asme y14.37 2019 product definition for composite parts standard. (1) meet the design requirements to ensure the quality of the machine, (2) meet the process requirements to facilitate structural manufacturing and inspection. It begins by defining dimensioning as specifying. Web geometric dimensioning and tolerancing (gd&t) is a system of symbols and standards used in engineering drawings and models to specify the required form, size, orientation, and location of parts and features. Dimensioning should follow these guidelines. Correct values must be given. It describes typical applications and minimum content requirements. Web the dimensions in the part drawing shall be marked. Dimensions must be placed in appropriate positions. To avoid confusion and the possibility of error, no dimension should be repeated twice on any sketch or drawing. Double dimensioning of a feature is not permitted. If a drawing is to be complete, so that the object represented by the drawing can be made as intended by the designer, it must tell. On a multiview drawing, dimensions should generally be placed between adjacent views. Do not leave any size, shape, or material in doubt. Web it establishes symbols, rules, definitions, requirements, defaults, and recommended practices for stating and interpreting gd&t and related requirements for use on engineering drawings, models defined in digital data files, and in related documents. According to iso 29845:2011,. Dimensions should be placed in the view which most clearly describes the feature being dimensioned. Do not leave any size, shape, or material in doubt. Web dimensioning practice once the shape of a part is defined with an orthographic drawing (i.e., in projections), the size information is added in the form of dimensions. Web the dimensions in the part drawing. Asme y14.37 2019 product definition for composite parts standard. Dimensioning should follow these guidelines. The general guideline is that each dimension should be placed on the view which shows the dimensioned feature most clearly, and which gives the clearest and least cluttered drawing. Web defines the types of engineering drawings most frequently used to establish engineering requirements. Web geometric dimensioning. This youtube channel is dedicated to teaching people how to improve their technical drawing skills. If a drawing is to be complete, so that the object represented by the drawing can be made as intended by the designer, it must tell two complete stories. Web geometric dimensioning and tolerancing (gd&t), tolerance analysis for fabrication, concepts of process variability, and metrology techniques are introduced and practiced. Features with & without size. Dimension elements dimensioning a drawing also identifies the tolerance (or accuracy) required for each dimension. Before an object can be built, complete information about both the size and shape of the object must be available. (1) meet the design requirements to ensure the quality of the machine, (2) meet the process requirements to facilitate structural manufacturing and inspection. Web the purpose of dimensioning is to provide a clear and complete description of an object. Web three principles of dimensioning must be followed: Do not leave any size, shape, or material in doubt. Complete engineering drawing exam preparation. Dimensions are expressed in specific units on the drawing with relevant information. This is a numerical value that is assigned to the size, shape, or location of the feature being dimensioned. Web the gsfc engineering drawing standards manual is the official source for the requirements and interpretations to be used in the development and presentation of engineering drawings and related documentation for the gsfc. This document discusses dimensioning practices for engineering drawings. Web defines the types of engineering drawings most frequently used to establish engineering requirements.![Dimensioning Its Types, System, Principles. [A Comprehensive Guide].](https://civilseek.com/wp-content/uploads/2018/10/dimensioning.jpg)

Dimensioning Its Types, System, Principles. [A Comprehensive Guide].

Types Of Dimensions In Engineering Drawing at GetDrawings Free download

Dimensioning Rules in Engineering Drawings YouTube

GENERAL RULES OF DIMENSIONING in Engineering Drawing YouTube

Rules Drawing at GetDrawings Free download

Technical Drawing Dimensions Design Talk

Rules For Dimensioning Mechanical Drawings Rules, Mechanic, Autocad

Dimensioning How To Clearly Communicate The Sizes Shapes Locations And

Dimensioning rules in engineering drawing

Rules For Dimensioning Mechanical Drawings YouTube

Web Dimensioning Practice Once The Shape Of A Part Is Defined With An Orthographic Drawing (I.e., In Projections), The Size Information Is Added In The Form Of Dimensions.

Dimension Lines Are The Thin Continuous Lines That Show The Extent And Direction Of The Dimension.

Web Every Dimension Must Have An Associated Tolerance, And That Tolerance Must Be Clearly Shown On The Drawing.

Web Dimensioning Is The Process Of Defining The Size, Form And Location Of Geometric Features And Components On An Engineering Drawing.

Related Post: