Chamfer Callout On Drawing

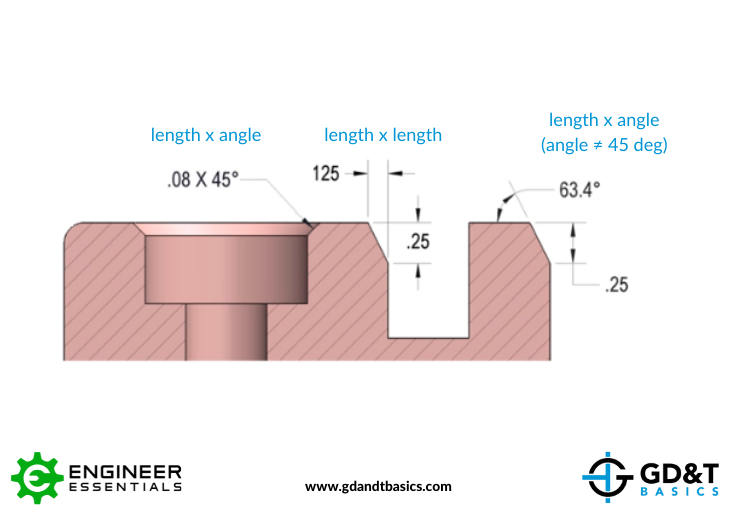

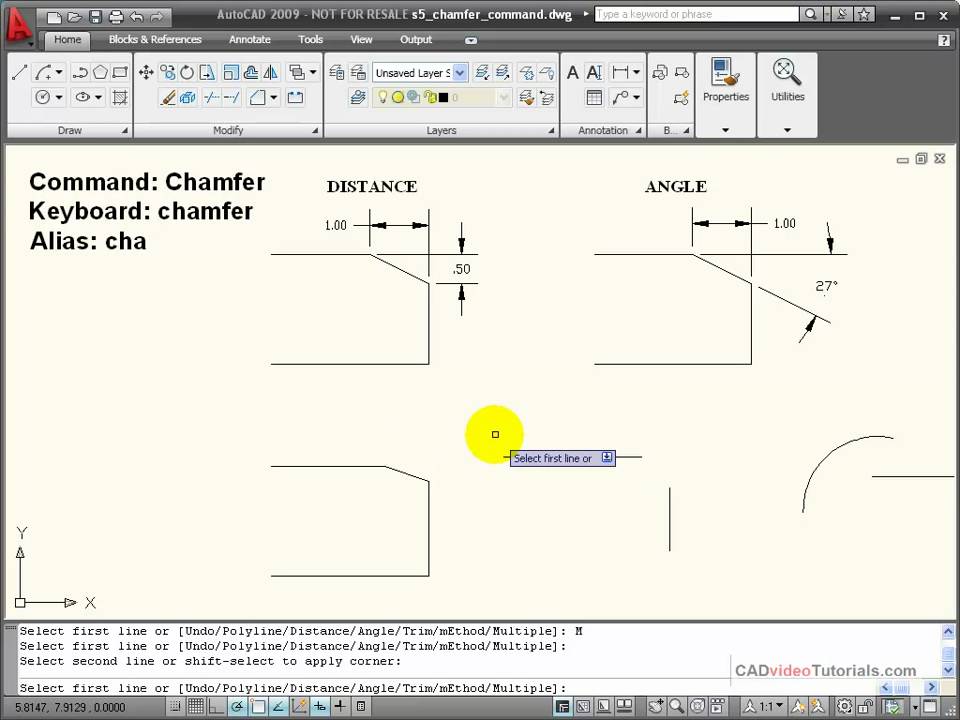

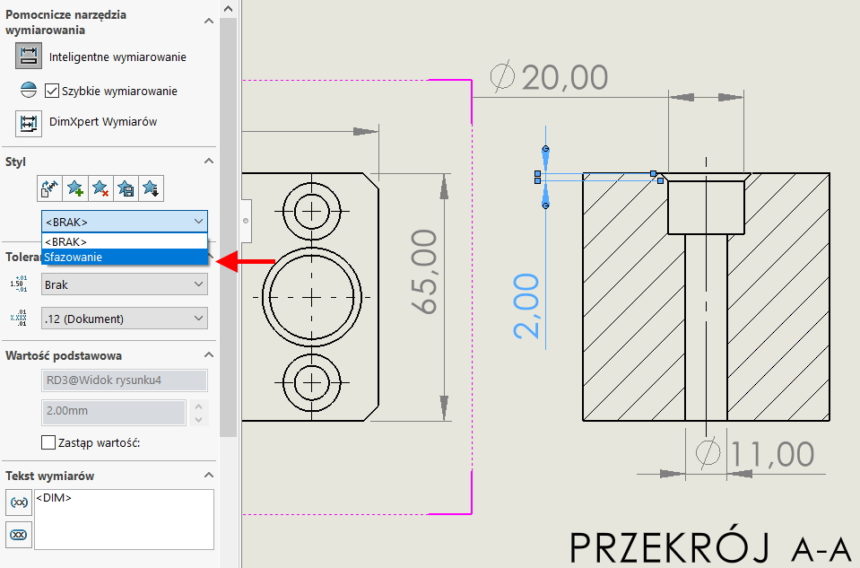

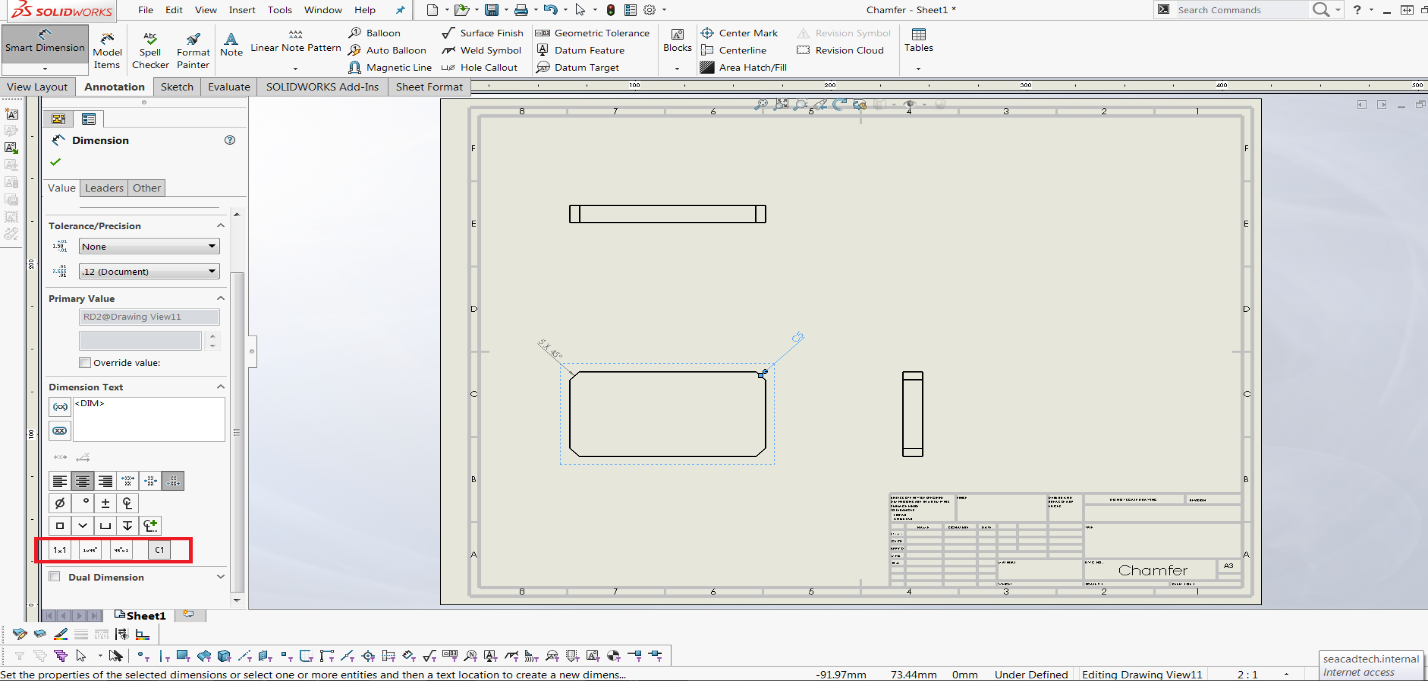

Chamfer Callout On Drawing - Creating a hole or thread callout: Web chamfers, rounds, fillets, and “break edges” are edge features that you may commonly see on your part drawings. Web break edge callouts are specified directly on the drawing to reference a certain surface or as a note e.g. Click chamfer dimension on the dimensions/relations toolbar or click tools > dimensions > chamfer. Create the dimensions needed (angle and/or distance) create leader note, inserting created dimensions as needed to create desired call out. In addition to the usual dimension display properties, chamfer dimensions have their own options for leader display, text display, and x display. Web what is the standard for a callout of a chamfer feature? I have a cylindrical part with a chamfer at each end. At times, the break edge specification may be contained in the general tolerance block such as shown below. Jan 17, 2017 03:23 pm. Another common application is to identify a common chamfer size on a component. Web dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. In this article, you will learn the proper way to do a chamfer callout, as well as how to do the callout in popular. However, one of those edges is on a diagonal face, so the 0.25mm chamfer is being shown as 0.33 (see below). They are used for a variety of reasons, which typically include: I am currently doing a drawing for a part where i have a 0.25mm chamfer on 2 edges. Hello, i recently changed a part for my company and. They are used for a variety of reasons, which typically include: Rfs is the default condition of all geometric tolerances by rule #2 of gd&t and requires no callout. Is it to call out the note with a leader (.25 x 45°) or to add two seperate dimensions (one linear and chamfer callout? Is this the correct notation for the. Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. Select a circle that is part of a hole feature, or a thread that is part of an external thread feature. What is the correct way to call out a 45 degree chamfer? Chamfers can also be specified. Jan 17, 2017 03:23 pm. Solidwork has a dimension style that. Select a circle that is part of a hole feature, or a thread that is part of an external thread feature. Erase created dimensions, if needed. In this article, you will learn the proper way to do a chamfer callout, as well as how to do the callout in. Another common application is to identify a common chamfer size on a component. Web to insert chamfer dimensions into a drawing: I have some experience with cad drawings, but started a new job, and the prints are small and very busy with lots of dims and lines. In this article, you will learn the proper way to do a chamfer. Web 7 feb 24 12:17. Web the typical callout will most often be used as part of a repeating pattern such as a bolt hole circle, to identify the hole sizes or angle between the holes. They are used for a variety of reasons, which typically include: This provides safety for both the part and the person using the part.. Web you can create the dimension wanted in a couple of steps. Select a circle that is part of a hole feature, or a thread that is part of an external thread feature. You must select the chamfered edge first. Chamfers are used to remove the sharp edges of a part. This provides safety for both the part and the. Web dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. .040 x 30) to my knowledge the.040 be the depth into the material and the 30 degrees is the angle from the centerline. I have some experience with cad drawings, but started a new job, and the. Designers can instruct with “break all edges” on the drawing and indicate a chamfer size, or they can add a note specifying that all sharp edges should be deburred. In addition to the usual dimension display properties, chamfer dimensions have their own options for leader display, text display, and x display. Working drawings need tolerances in addition to functional size. So that i could change it to standard leader option ? If no angle is given the chamfer is assumed to be at 45 degrees. Has anyone out there ever seen (c/r) used as a callout for an optional chamfer/radius? You must select the chamfered edge first. Is the correct callout for this 2x 0.031 x 45° or does each chamfer need to be noted individually? Is it in the standard? What is the correct way to call out a 45 degree chamfer? In this article, you will learn the proper way to do a chamfer callout, as well as how to do the callout in popular software programs. Web 7 feb 24 12:17. Web when using a leader to call out a chamfer (ie. Web regardless of feature size simply means that whatever gd&t callout you make, is controlled independently of the size dimension of the part. Web 10 aug 07 12:39. Designers can instruct with “break all edges” on the drawing and indicate a chamfer size, or they can add a note specifying that all sharp edges should be deburred. How to make a break edge. Web to insert chamfer dimensions into a drawing: Chamfers can also be specified by giving both legs of the chamfer such as:

Chamfer Dimensioning GD&T Basics

AutoCAD Tutorial Using the CHAMFER Command YouTube

Quickly insert a chamfer dimension in drawings SOLIDWORKS BLOG

How to Use SolidWorks Sketch Chamfer Tool Tutorial for Beginners

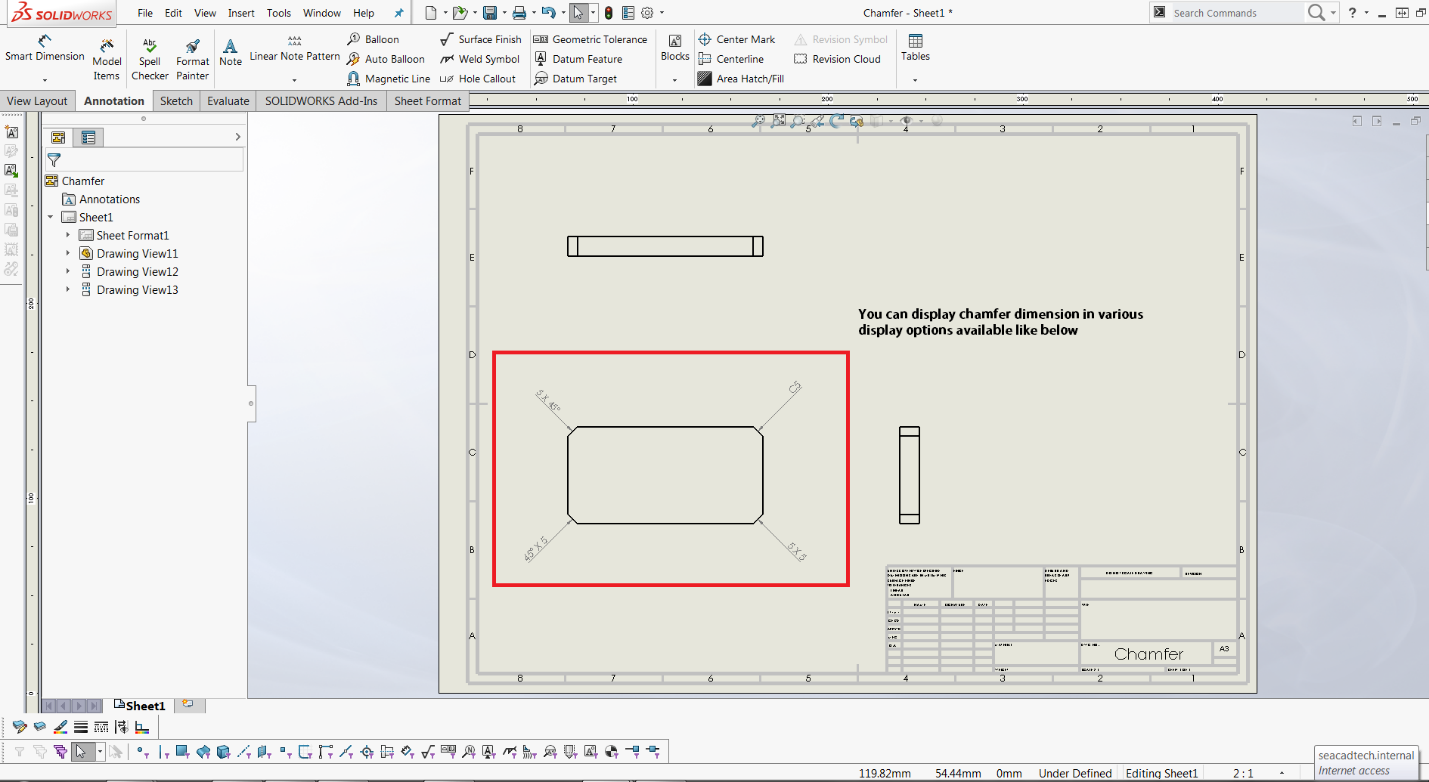

Steps to add chamfer dimension in 2D drawing SEACAD

Steps to add chamfer dimension in 2D drawing SEACAD

SolidWorks Tutorial How to Add Chamfer Dimension In Solidworks Drawing

Dimensioning standards

Introduction to AutoCAD Chamfer YouTube

Steps to add chamfer dimension in 2D drawing SEACAD

Web Steps Copy Link.

This Is Good Only For Sketches And Preliminary Design Drawings.

Web The Typical Callout Will Most Often Be Used As Part Of A Repeating Pattern Such As A Bolt Hole Circle, To Identify The Hole Sizes Or Angle Between The Holes.

Working Drawings Need Tolerances In Addition To Functional Size Values.

Related Post: